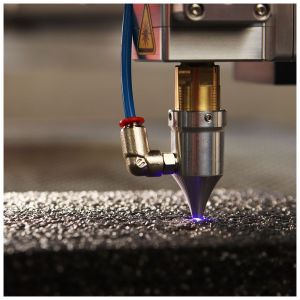

High-Pressure Air Assist Nozzle is an invaluable resource for cutting and engraving with a laser. Being able to increase the speed of laser cutting and engraving by up to 6.5 times compared to the base speed as well as substantially improve the quality of the processed objects makes it a perfect tool for anyone who wants to produce top-notch quality items with uniform and well-defined features.

High-Pressure Air Assist Nozzle is an invaluable resource for cutting and engraving with a laser. Being able to increase the speed of laser cutting and engraving by up to 6.5 times compared to the base speed as well as substantially improve the quality of the processed objects makes it a perfect tool for anyone who wants to produce top-notch quality items with uniform and well-defined features. Purchasing the nozzle is also a pragmatic choice as it extends time intervals between subsequent cleaning routines and improves the longevity of the front lens by safeguarding it from smoke and dust particles. The length of the High-Pressure Air Assist Nozzle can be adjusted for different material thicknesses by +8/-4 mm for the XF+ Laser Head or +5/-4 mm for the XF+ Laser Head with the µSpot Lens Upgrade. The High-Pressure Air-Assist Nozzle is compatible with the new generation of XF+ Laser Heads (with or without the µSpot Lens Upgrade). A special sleeve is shipped for the XF+ Laser Head without the µSpot Lens Upgrade variant to ensure compatibility.

High-Pressure Air-Assist Nozzle Kit contains:

- High-Pressure Air-Assist Nozzle

- XF+ Lens Adapter Sleeve

- Air Pipe Connector (M5 / 4 mm)

- O-Ring Seal (8x1 FPM)

- Air Pipe (Ø4mm; 7 m long)

- Lens Spanner Wrench

- Four M3x3 Screws

- Four M3x5 Screws

Suitable compressor

Any compressor can connect to the air nozzle, but in order for each material to be processed, you need to experimentally select the flow parameter. With small devices, you may not achieve the desired results.

Of course, the greater the capacity of the tank and the capacity of the compressor, the greater the airflow that can be set on the air nozzle and the greater the comfort of work (i.e. the compressor will not turn on so often to refill the tank).

Our experiments show that a flow value of 10-15 l/min is the upper limit and completely sufficient for most materials when cutting.

Therefore, we would recommend a compressor with a real airflow of 10-12 l/min and a tank of at least 50l.

However, nothing is stopping you from trying a smaller compressor.